MIXEL is now a part of GMM Pfaudler

Side entry agitator SIDE JET has been designed to equip large capacity tanks (up to 50,000 m³). Those tanks are currently integrated to processes in chemical, petrochemical, agro food and water treatment industries.Blended products are often hazardous, viscous and corrosive ones.This type of agitator complies with ATEX standard. JET turret guides agitation shaft and holds sealing system box. Upload booklet.

Agitator for storage, homogenization and suspending solids, blending and heat keeping. Chemistry, petrochemistry, oïl & gas…

Hydrocarbons, oil additives, oils, food additives, paint and coloring, industrial effluents.

Guiding turret for SIDE JET Agitator is made of FGS400 cast iron. Agitation parts can be made of carbon steel, SS304 or 316L, Alloy, or coated carbon steel (with rubber, plastic…)

Thanks to JET, maintenance technicians can complete servicing of the mechanical seal in roughly four hours, in safe conditions.

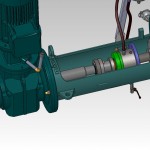

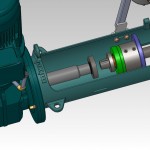

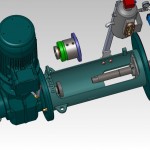

Here are pictures of sealing box dismantling stages showing extraction system of JET guiding turret, for highly secured operation.

Disengaged sealing box and guiding shaft blocked by a ring

Uncoupling of driving shaft

Sliding motion of guiding shaft in order to release sealing box

Released sealing system box ready for maintenance

Dismantling, maintenance and reassembling of sealing box can be operated with empty or full tank.